Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies

July 2013

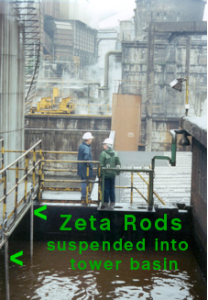

TVA Cooling Water Conservation Project

Abstract: Zeta Rod® Water Management Systems were selected to be utilized as the water treatment system of choice for the recirculating open-loop chillers, heat exchangers and cooling towers for the two HVAC Central Plants at a U.S. Government Data Facility in the Southeastern United States. The purpose of the system was to deliver significant water conservation while protecting critical cooling equipment in a manner consistent with a well managed traditional chemical water treatment program. The Zeta Rod system was included as part of an Energy & Water Conservation Project implemented by the Tennessee Valley Authority (TVA).

- 22% less make up water used

- 65% less waste water sent to the sewer

- 5.8 Million gallons of water saved during the first year

Click here for full Case Study: TVA Cooling Water Conservation Project