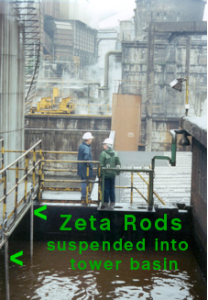

Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies

September 2007

Zeta Rod Reverse Osmosis 簡報檔-英文: Foxconn Group, Shenzhen China

Frigaid Corporation Ltd. — Zeta Rod Distributor for Asia www.zetarod.com.tw

Zeta Rods installed into a Foxconn Reverse Osmosis (RO) plant in Shenzhen China increases permeate rate from 66.6% to 76.4%, reduces wastewater by 15% and prevents fouling of RO membranes allowing for energy savings and increased productivity.