Zeta Library Collections: Technical Papers

Zeta Library Collections: Technical Papers

July 2009

USACE ERDC/CERL

Demonstration of Electronic Capacitor-Based Water Treatment System for Application at Military Installations

Zeta Library Collections: Technical Papers

Zeta Library Collections: Technical Papers

July 2009

USACE ERDC/CERL

Demonstration of Electronic Capacitor-Based Water Treatment System for Application at Military Installations

Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies

September 2007

Zeta Rod Reverse Osmosis 簡報檔-英文: Foxconn Group, Shenzhen China

Frigaid Corporation Ltd. — Zeta Rod Distributor for Asia www.zetarod.com.tw

Zeta Rods installed into a Foxconn Reverse Osmosis (RO) plant in Shenzhen China increases permeate rate from 66.6% to 76.4%, reduces wastewater by 15% and prevents fouling of RO membranes allowing for energy savings and increased productivity.

Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies

September 2007

Zeta Rod 簡報檔-英文 Formosa Plastics | Nan-Ya Jing Hsin Co-Gen Power Plant

Frigad Corporation Limited — Zeta Rod Taiwan Distributor www.zetarod.com.tw

The 10,000 RT cooling tower at Formosa Plastics Group, Nan-Ya Plastics Jing-Hsin Power Plant in Taiwan uses Zeta Rod systems for fouling prevention, water conservation, chemical reduction and enhanced worker health & safety.

Zeta Library Collections: Technical Papers

July 2007

Abstract:

…Four different application case studies are presented in this paper in which High Voltage Capacitance Based (HVCB) technology was used to control biofouling. The applications include an evaporative cooling wall in a greenhouse in Oracle, Arizona; a cooling tower–condenser application in Phoenix, Arizona (study performed by Arizona State University under a U.S. Department of Energy grant); a cooling tower system using reclaimed industrial waste water at a wafer facility in Camas, WA; and a piping system for a major utility plant (Tennessee Valley Authority – TVA) using river water.

Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies

September 2005

Formosa Plastics | Nan-Ya Chia-Yi Plant | Zeta Rod Case Study 簡報檔-英文

Frigaid Corporation Limited, Zeta Rod Asia Distributor www.zetarod.com.tw

Zeta Rod systems successfully provide water conservation, chemical eliminations and reductions, biofouling & scale prevention in this PVC plant.

click here to link to the Formosa Group, Nan-Ya Plastics Case Study

April 2003

Mill Valley Car Wash water conservation, cost control and customer satisfaction

Within 60 days, results delivered by the Zeta Rods were significant:

• Reduced water consumption per vehicle from 48.75 gallons per car (gpc) to 35.51 gpc; a net reduction of 27% per vehicle

• 235,000 gallons of water saved in 60 days

• 38% drop in the total per vehicle washing cost

click here to link to the Mil Valley Car Wash case study

Operations Manager Eric Traband: “I’m sold on this [Zeta Rod] system. What I have now is an odor-free and bacteria-controlled environment, I’m using a lot less water, and cutting my overall costs. This system is a winner.”

Within 60 days, results of the Zeta Rod installation into the Mill Valley Car Wash were impressive:

• Reduced water consumption per vehicle from 48.75 gallons per car (gpc) to 35.51 gpc; a net reduction of 27% per vehicle

• 235,000 gallons of water saved in 60 days

• 38% drop in the total per vehicle washing cost

MILL VALLEY, Calif., April 2003 – Car wash Operations Manager, Eric Traband, recently demonstrated to his boss why he had been named a national Car Wash Manager of the Year in 2000. Traband, an 11-year veteran of the industry, seized an opportunity to help trim his carwash operation’s spiraling water costs and, at the same time, deliver better, more efficient service to his growing roster of customers. Continue reading

Tucson, Arizona: Zeta Corporation has established that its patented Zeta Rod® technology is another weapon in the battle against legionella. Zeta Rod systems will remove and prevent recurrence of biofilm and associated scale that shelters legionella bacteria inside potable water systems and in cooling towers. Continue reading

Tucson, Arizona: Zeta Corporation has established that its patented Zeta Rod® technology is another weapon in the battle against legionella. Zeta Rod systems will remove and prevent recurrence of biofilm and associated scale that shelters legionella bacteria inside potable water systems and in cooling towers. Continue reading

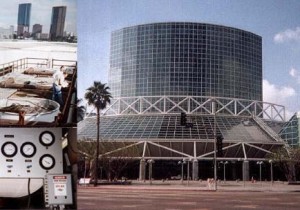

Tucson, Ariz., April 10, 2002 — After three years of closely monitored performance at the Los Angeles Convention Center of Zeta Corporation’s Zeta Rod™ system, the convention center won a city-wide environmental award and realized a three-year accumulated savings of $150,000.

Zeta Rod System at Los Angeles Convention Center

In making the announcement, Zeta President M. Michael Pitts, Jr, Ph.D. said that the City of Los Angeles Quality and Productivity Commission, after an eight-month evaluation process, singled out 20 city departments out of 114 applicants for honors in the categories of Customer Service, Environmental, Entrepreneurship, E‑Business and Innovation and Creativity.

The Los Angeles Convention Center facilities staff won the Environmental Award for “the elimination of scale and corrosion cleaning, increased employee safety, reduced water consumption, longer equipment life and an annual savings of $50,000” in the operation of the huge building’s chillers and cooling towers. Continue reading

Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies

November 2001

BP Manufacturing Solutions reduces chemical and filtration costs, GMPT Flint, Michigan USA