http://www.waterworld.com/content/ww/en/articles/2002/04/zeta-rod-wins-environmental-award-for-los-angeles-convention-center.html

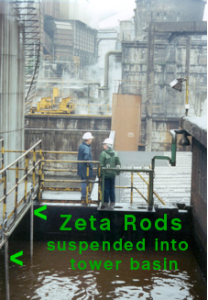

Tucson, Ariz., April 10, 2002 — After three years of closely monitored performance at the Los Angeles Convention Center of Zeta Corporation’s Zeta Rod™ system, the convention center won a city-wide environmental award and realized a three-year accumulated savings of $150,000.

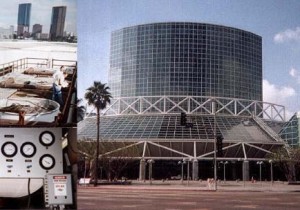

Zeta Rod System at Los Angeles Convention Center

In making the announcement, Zeta President M. Michael Pitts, Jr, Ph.D. said that the City of Los Angeles Quality and Productivity Commission, after an eight-month evaluation process, singled out 20 city departments out of 114 applicants for honors in the categories of Customer Service, Environmental, Entrepreneurship, E‑Business and Innovation and Creativity.

The Los Angeles Convention Center facilities staff won the Environmental Award for “the elimination of scale and corrosion cleaning, increased employee safety, reduced water consumption, longer equipment life and an annual savings of $50,000” in the operation of the huge building’s chillers and cooling towers. Continue reading →

Zeta Library Collections: Case Studies

Zeta Library Collections: Case Studies