June 10, 2016

June 10, 2016

Tucson, Arizona — Zeta Corporation and Nanocera are pleased to announce the formation of a strategic alliance co-marketing sustainable products and technical services to industry. The two companies will combine development efforts in key industrial markets where customer productivity and sustainability interests overlap. Principals at both companies have been interested in a collaboration for several years and look forward to promoting the alliance.

Nanocera offers leading edge, environmentally advantaged conversion coating technologies, which provide superior corrosion resistance and paint adhesion, eliminate damaging phosphates and regulated heavy metals, and significantly reduce total operating costs, including lower energy and water usage.

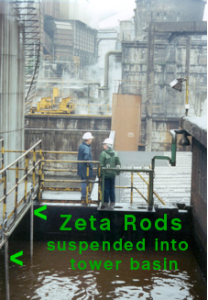

Zeta Corporation manufactures and markets Zeta Rod® systems, which significantly improve water and energy conservation, optimize the performance of industrial fluids, reduce water treatment chemical usage, and control scale and biological fouling in water systems.

For more information, please contact:

NANOCERA

Blair Imbody

Founder/CEO

(520) 909‑0168

ZETA CORPORATION

Carolyn B. Pitts

President/CEO

888−785−9660