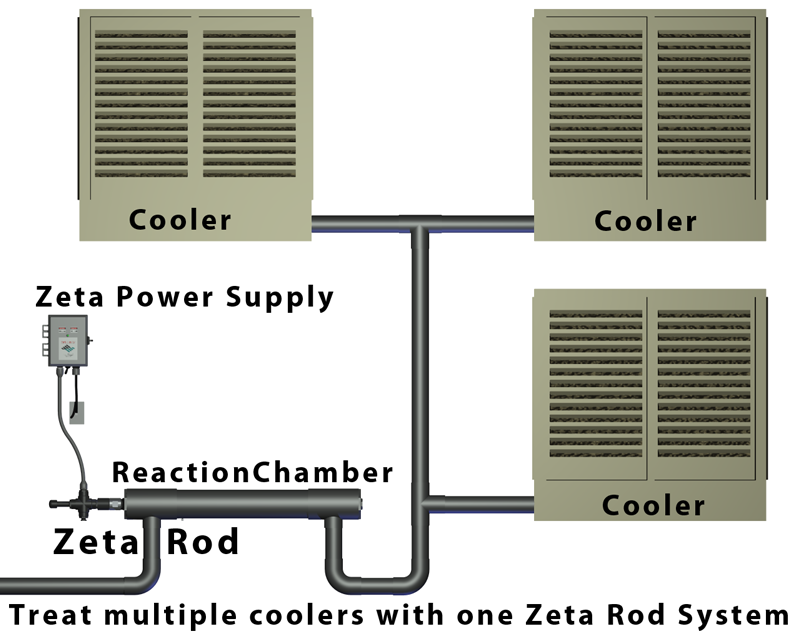

Are you interested in protecting and reducing maintenance on evaporative cooling equipment, significantly extending the life of cooler pads and CELdek® media, conserving water, and eliminating odor and scale buildup? Zeta Rod® electronic capacitor-based water treatment systems deliver these benefits and more with a simple installation into the main water line feeding one or more evaporative coolers.

The Problem:

Evaporative “Swamp” Coolers are a relatively low cost method of providing comfort cooling in dry climates; especially in large open areas such as warehouses, open bay auto repair facilities, vehicle barns, hangars, and animal shelters.

While this may be the most economically practical method of providing cooling in these situations, everyone tasked with maintaining evaporative cooling systems knows that there are many problems associated with their use. Heavy scale formation, foul odors and high maintenance costs are commonly accepted as unavoidable. The resulting damage causes many problems:

- Salty scale encrustation on the exterior of the cooler housing penetrates the protective finish and accelerates corrosion.

- Scale fills the pore space of the cooler pads and fills the louvers of the housing panels restricting air flow and reducing the output of cool air. Media efficiency and service life are greatly reduced.

- Scale accumulation inside the pumps and tubing reduces water flow and cooling efficiency.

- Scale causes float valves to stick open or closed, requiring expenditures for labor and parts.

- Bacterial growth produces foul odors which are unpleasant and can present a threat to human health.

Zeta Rod Systems Solve Problems Associated with Evaporative Coolers

Zeta Rod systems are an electronic dispersion technology that effectively boosts the natural surface charge of organic and inorganic particles in water. For evaporative cooling applications, the Zeta Rod is inserted into the piping that feeds the coolers. The system consists of the Zeta Rod, which is an insulated ceramic probe, energized by a power supply that converts standard 110–220 VAC into 30 kV DC. The Zeta Rod is inserted into a grounded stainless steel chamber that is plumbed into the piping, creating a powerful cylindrical capacitor. As water flows through the chamber, bacteria and scale forming particles receive a strong boost their natural surface charge. The strongly charged particles repel one another and remain in stable dispersion, rather than uniting to form scale or allowing the formation of microbial colonies. The reduction of bacterial growth eliminates the principal cause of foul odors from which the name “swamp cooler” originated.

The Benefits:

- Scale formation on wetted surfaces is eliminated. Evaporated salts wash off with a garden hose.

- Extends life of Aspen pads by 2–3 years, and CELdek® media indefinitely. Eliminates the need for mid-season maintenance and pad changes.

- Service life of the cooler and frame is extended by 50% or more.

- The Zeta Rods allows for reduction of bleed, while maintaining full efficiency of the cooler. Achieve 25% or more water conservation.

- More effective cooling achieved because wetted surfaces are prevented from fouling.

- Zeta Rod requires no maintenance. Electrical use is almost too low to measure. A Zeta Rod system will pay for itself quickly in reduced cooler maintenance time and replacement parts. Workers are happier with fresh smelling cool air.